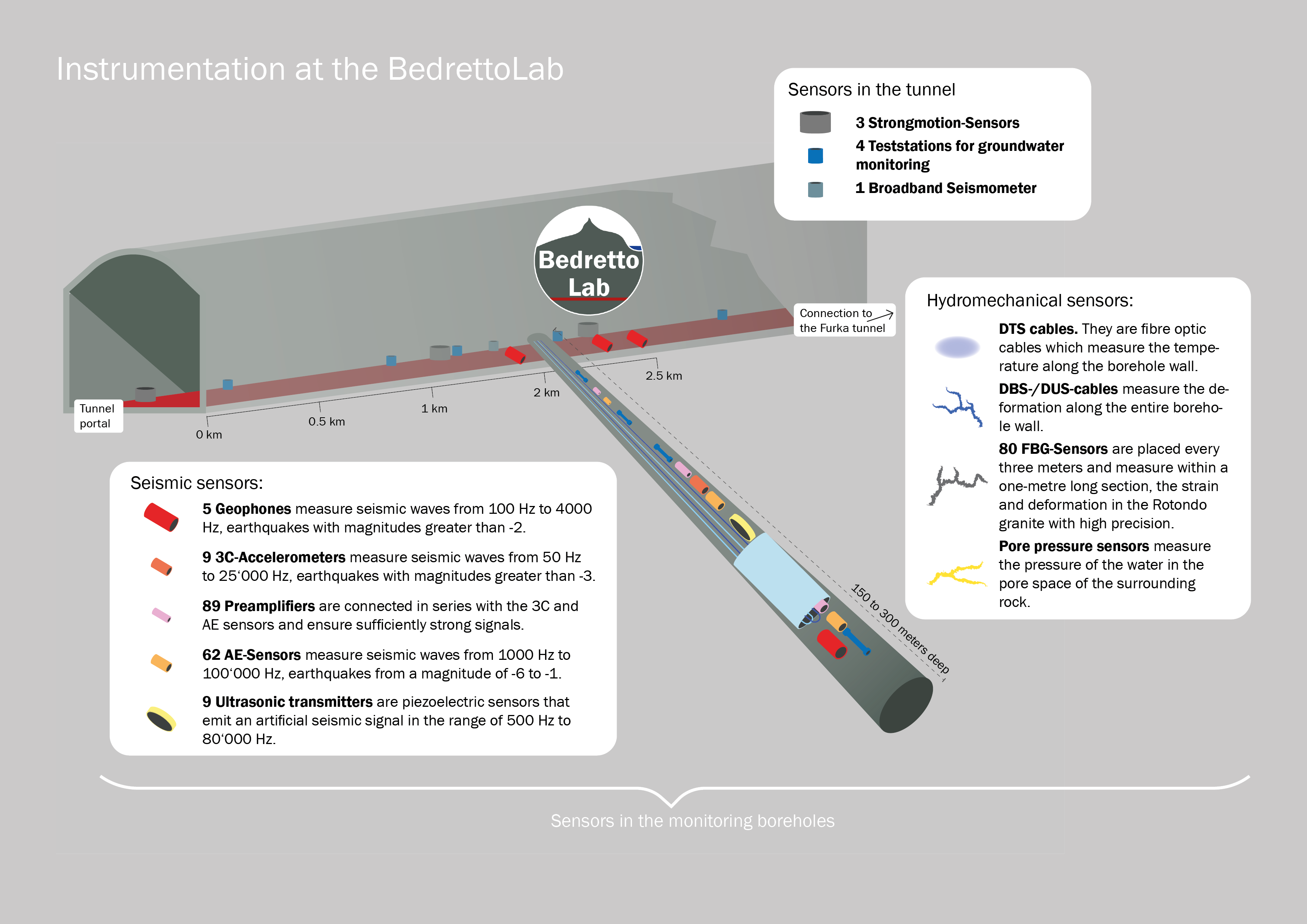

Sensors of the Bedretto Reservoir Project Monitoring Network

In the framework of the Bedretto Reservoir Project a medium scale reservoir is created. This means that two boreholes will be connected by fractures to allow water circulation from one borehole to the other. In order to observe the processes during fracture generation and water circulation in detail, the rock volume is monitored using a variety of instruments. Several sensors were newly developed under the lead of Dr. Katrin Plenkers to meet the harsh conditions in the Bedretto laboratory. In summer 2020 and 2021 an expert team has installed the monitoring system in the monitoring boreholes of 101 meters to 300 meters length.

In-situ Acoustic Emission sensor

Because pendulum-based seismometers like geophones or accelerometers are not capable to record seismic waves above 25 kHz, the Bedretto Reservoir Project is monitored in addition by piezoelectric In-situ Acoustic Emission (AE) sensors. These sensors are about ten times more sensitive in the kHz range than other seismic sensors and are capable to record frequencies up to several hundred kHz.

For this project a new sensor was developed by GMuG GmbH that is custom made for the Bedretto project in terms of frequency range, sensitivity and reduced resonances. It is optimized for the monitoring of the frequency range 1 kHz to 80 kHz, which allows us to monitor the formation of small cracks of centimeter size within the reservoir, an important observation in order to understand the damage evolution. The sensor is made for installation via cementation and able to withstand high pressures > 100 bar. Eight to sixteen AE sensors are placed per borehole. Data is digitized with a 200 kHz sampling frequency.

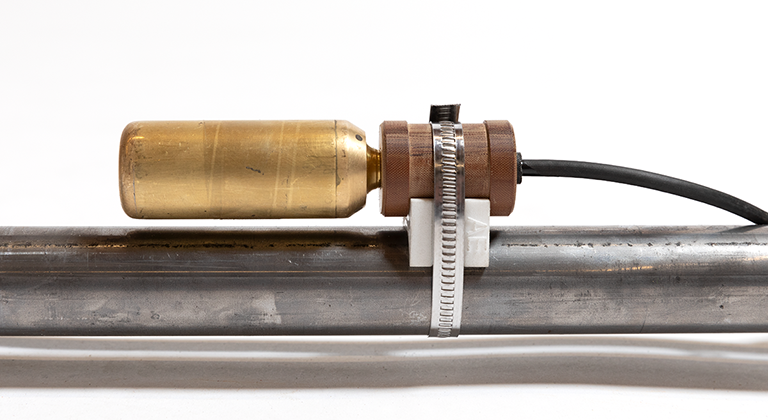

High-frequency accelerometer

Similar to geophones, accelerometers are pendulum-based seismometers that are capable to record seismic waves, but accelerometers are able to record higher frequencies and outperform geophones in the kHz range. The recording of kHz waves is necessary to record magnitudes smaller than -2, which correspond to fractures on meter or centimeter scale.

In the Bedretto Reservoir Project we install two kinds of accelerometers: First, we decided for six Wilcoxon 736 sensors, as this type of sensor covers the broadest frequency band up to 25 kHz. Second, we installed three Endevco 45A19 sensors from Megitt that are capable to record up to 6 kHz and come with a higher sensitivity. IMS South Africa built both sensors into a housing that allows cementing the sensors in the boreholes and that allow operations at pressures up to 100 bar. We relied on the experiences from IMS in sensor construction, because building a housing without introducing unwanted resonances is very challenging in this frequency range. One to three accelerometers are installed per borehole.

Geophones

Geophones are pendulum-based seismometers that are capable to measure seismic waves emitted by small seismic events.

We install three 100Hz geophones manufactured by IMS South Africa in the deep boreholes. IMS is the world-leader in seismic monitoring in mines. Based on their experience, our geophones were retrofitted specially to meet the requirements of the Bedretto Reservoir Project: The sensors must be able to record high frequencies up to the kHz range, the sensors must be spurious free when recording seismic events from short distances and able to withstand up to 100 bar background pressure. During the experiment, the geophones will allow us to record larger seismic events (we expect seismic events with magnitudes up to M 0.5) without having clipped signals. The geophone network is extended during the experiment with some additional 100Hz geophones installed temporarily in short boreholes at the tunnel and a geophone chain installed in the injection/extraction borehole.

Pore-Pressure Sensors and Multi-packer

Pore pressure refers to the pressure of groundwater held within a soil or rock, in gaps between particles (pores). To measure pore pressure in different intervals of the experiment volume, we installed a multi-packer that separates the monitoring borehole "MB2" into several segments, each coming with one pressure sensor. Our multi-packer comes with 7 intervals separated by packers of 1m length. The intervals were chosen based on the observed fracture/fault clusters from the core and logging observations.

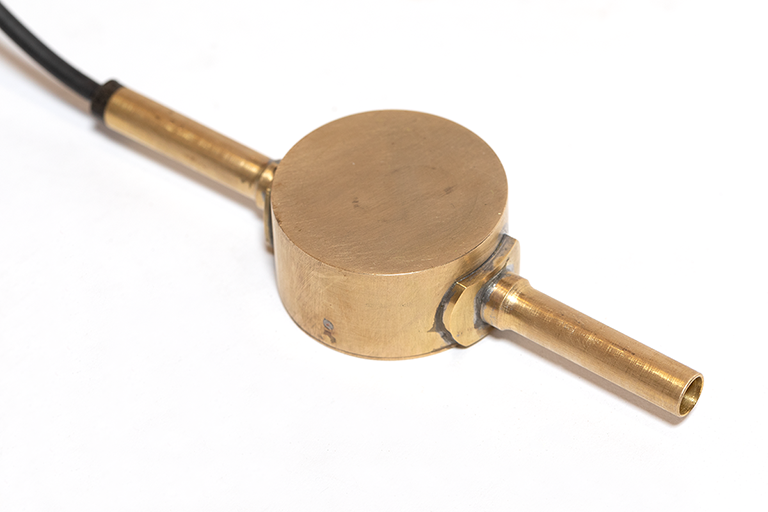

Ultrasonic Transmitter

While seismic receivers (geophones, accelerometers, AE sensors) are able to record passive seismic signals, they are also suitable to record active signals, i.e. man-made signals emitted in order to scan the rock volume.

In the BRP project, we aim at installing sources within the monitoring boreholes that are suitable for cementation and emit in the long term a repeatable signal. Because we are interested in the evolution of fracture geometries of centimeter to meter scale, the source should come with a considerable bandwidth. For this reason, we install ultrasonic transmitter manufactured by GMuG and retrofitted to withstand the pressures in BRP. GMuG is specialized on developing custom-made sensors in underground experiments. The transmitters are based on piezoelectric ceramics that emit after receiving a 1200 V delta impulse, a stress wave similar to seismic waves. Two transmitters are placed per borehole and distributed in such a way that the reservoir center is fully scanned from all directions.